Next generation textile sorting technology for a circular economy

We are a solution provider supplying intelligent sorting technology for augmented and automated sorting needed to transform discarded textiles into valuable resources and to reduce textile waste through reuse, repair, upcycling and recycling.

Our vision is to enable the transformation of the textile industry towards a circular economy, ensuring discarded textiles are kept in the value chain, following the waste hierarchy.

Solutions

Improve sorting efficiency

Reduce process costs by optimising tedious and error-prone manual processes through augmentation and automation.

Consistently sort to highest value

Maximise the value of the feedstock you receive, constantly optimising your products.

Unlock new secondhand markets

Establish and unlock new sales channels to secondhand retailers, fashion brands with their own recommerce offers and textile recyclers.

Contribute to a sustainable future

Comply with upcoming regulations and sustainability goals to provide more sustainable services and boost global competitiveness.

Evaluate your collection streams

Keep an overview of the quality of feedstock streams utilising automated evaluation.

Emerging secondhand markets and recommerce services offer a high potential to address the sustainability challenges of the textile industry. Textile sorters play a key role in enabling these business models. Through accurate and efficient sorting of discarded garments, unlocked by our reverse.fashion technology, they are able to provide reliable feedstock streams and customer-specific collections. While contributing to the circular economy, the technology thereby also maximises the worth of the sorters’ goods, fostering both sustainability and profitability.

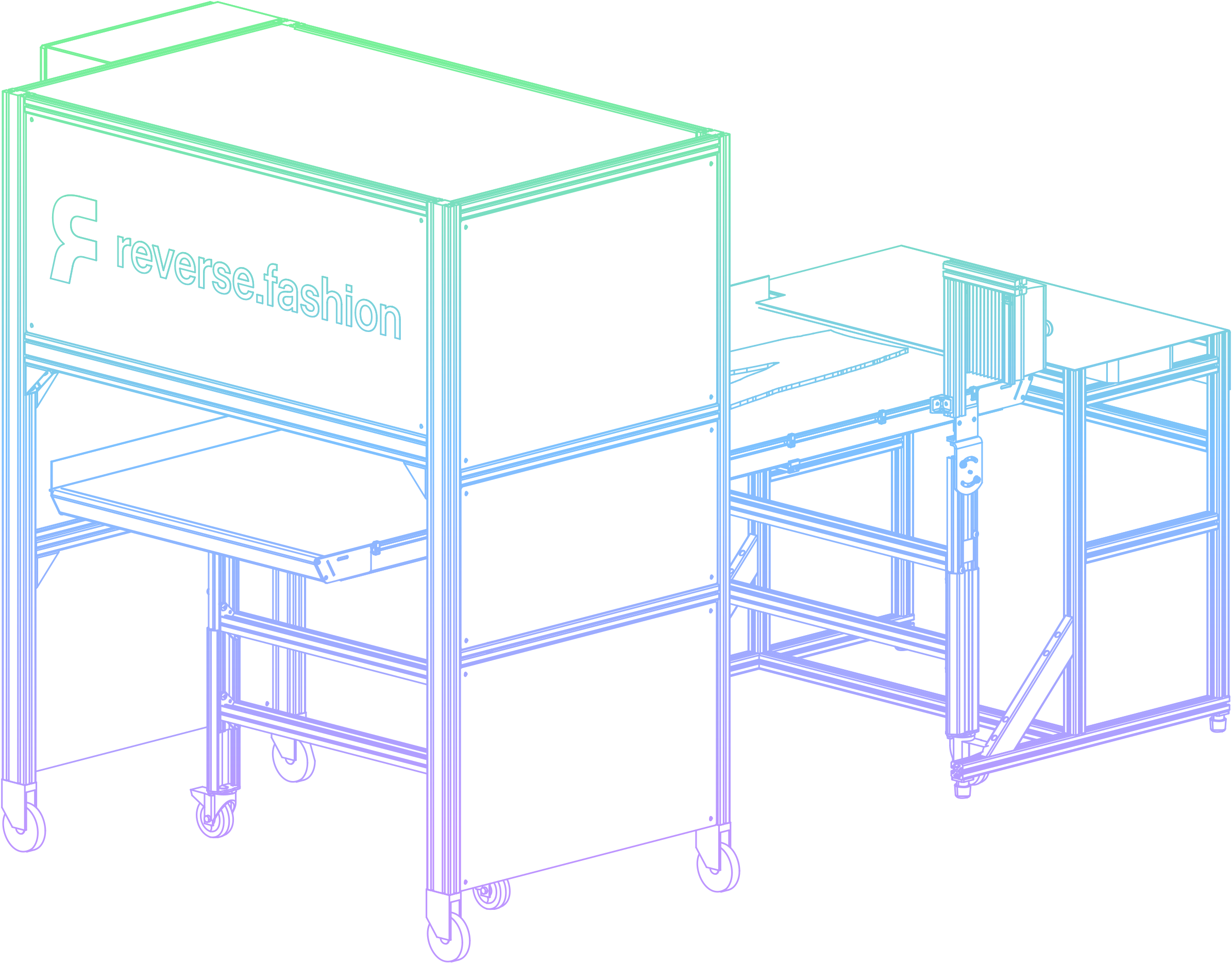

Automated sorting station

DPP-based sorting

AI-based computer vision

compatible with spectroscopy solutions

Our automated sorting system utilizes image recognition and RFID technology to efficiently process discarded textiles. As Textiles move along a conveyor belt, they are scanned by a state-of-the-art camera system. The sorting technology utilizes artificial intelligence (AI) for accurate textile recognition and a software framework designed to optimize sorting. This system categorizes each item, exceeding traditional manual methods by detecting multiple characteristics. Additionally, the system will allow access to Digital Product Passport data once the DPP has been enforced. These capabilities enable the precise allocation of products to both existing and emerging second hand business streams, including secondhand retail, recommerce, repair services and upcycling.

AI-based sorting algorithm

objective and accurate decision making

efficient processing through one stage sorting and automated decision making

multiple attribute detection such as quality, brand, product type, size, style for fine granular allocation to fractions

quality assessment of collection streams enabled through automated quality detection

flexible and instant adaptation to feedstock requirements

High quality training data

Dataset of defective clothing

Based on high-resolution images captured using the only known scanning system that provides the necessary resolution to detect even small defects. The images are taken in a real-world industrial settings.

3D Dataset

3D images captured with specialized scanning systems. Synchronous to 2D images to detect further details like wrinkles.

Product Attribute Datasets

Millions of images, including post-consumer clothing and studio shots. Labels are provided for product category, type, resale value, and, brand.

Additionally, several open datasets have been post-processed to fit our data model and serve as training data.

reverse.fashion was founded to offer high-tech technology for sorting used textiles and thus create the transformation to a circular economy for textiles. The technology we are developing builds up on two research and development projects that have been conducted in a collaboration between circular.fashion and Technische Universität Berlin. Within these projects, computer vision, DPP and spectroscopy technology for textile sorting has been developed, which is being transferred to the new entity reverse.fashion as a basis for our further development. We will further develop these solutions and bring them to market.

About us

We are a dedicated team of tech enthusiasts on a mission to make a real impact on sustainability. We combine years of experience in the sorting industry and in managing companies with substantial academic backgrounds and profound expertise for machine learning, software development and optical engineering. What unites us is our passion for circularity and sustainability. Together, we are eager to apply our expertise to create solutions that truly advance the circular economy in the textile industry.

Team

Mario Osterwalder

Co-founder

Managing director

Dr. Karsten Pufahl

Co-founder

CTO

Paul Doertenbach

Co-founder

Strategy

Options to work together

Experience our solutions

Get a free demonstration of our functional prototype to get an idea of how it works.

Run on-site tests from 2025 on – get in touch now to discuss your options!

Become a system partner

Indicate your interest in transitioning to automated sorting and have the chance to contribute to our sorting advancements. Shape our solutions according to your needs.

Keep up to date

Follow us on social media and view our project website to be informed about new developments.

Join our mission to shape a future where textile waste is minimized by utilizing our advanced sorting technology. Let's make a significant impact together – your expertise is crucial in driving this change.